There are several methods for treating waste, one of the most advanced methods is called flash pyrolysis, the basic idea of the method is high temperature heating in vacuum.

Pyrolysis is the thermal decomposition of materials at elevated temperatures in an inert atmosphere. It involves a change of chemical composition. The word is coined from the Greek-derived elements pyro "fire" and lysis "separating". The process is used heavily in the chemical industry, for example, to produce ethylene, many forms of carbon, and other chemicals from petroleum, coal, and even wood, to produce coke from coal. Aspirational applications of pyrolysis would convert biomass into syngas and biochar, waste plastics back into usable oil, or waste into safely disposable substances.

Flash vacuum pyrolysis (FVP) is a technique in organic synthesis. It entails heating a precursor molecule intensely and briefly. Two key parameters are the temperature and duration (or residence time), which are adjusted to optimize yield, conversion, and avoidance of intractable products.

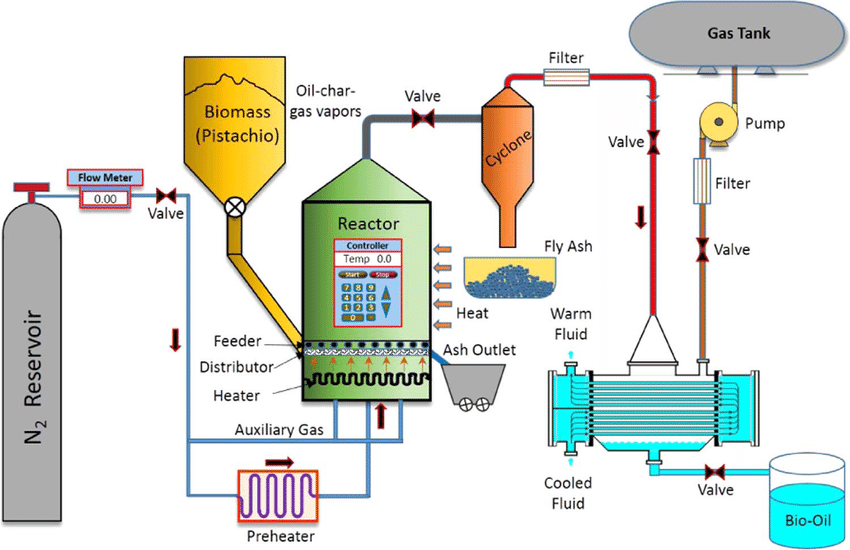

Often the experiment entails volatilizing a precursor, which is drawn through a "hot zone" followed by rapid condensation. The apparatus typically is conducted under dynamic vacuum. The hot zone must impart heat to the gaseous molecules, so it is generally packed with solids to induce gas-solid collisions. The packing material is generally chemically inert, such as quartz.

the precursor volatilizes with gentle heating and under vacuum, the precursor fragments or rearranges in the hot zone, and finally, the products are collected by rapid cooling. Rapid post-reaction cooling and the dilution inherent in gases both suppress bimolecular degradation pathways.

Flash pyrolysis (sometimes called very fast pyrolysis), characterized by rapid heating rates (>1000 °C/s) and high reaction temperatures (900–1300 °C), has been shown to afford high yields of bio-oil with low resulting water content and conversion efficiencies of up to 70% . The residence times used are even shorter than those of fast pyrolysis, typically less than 0.5 s. To obtain such high heating and heat transfer rates, the biomass feedstock particle size must be as small as is practically possible, usually around 105–250 μm (60–140 mesh size).

The extremely high temperature, up to 1000°C, offers chemists new chemical space where they can perform a wide range of ntramolecular reactions like rearrangements, ring closure or opening reactions, monomerization reactions and pyrolysis. The Flash Pyrolysis Platform gives a quick and clean entry to reactions enabling the synthesis of compounds that are otherwise complex or unsuccessful to obtain.